Semi-finished products

Your specialist for semi-finished products

Electrical contacts in switching applications are responsible for closing and opening circuits. When closed, they are engineered to ensure the transmission of information and currents with minimum losses. The advantageous material properties of silver and silver alloys make them the ideal choice for contact materials. Our product portfolio includes silver-based semi-finished contact materials, such as wires, profiles, and contact tips. As a global market leader for electrical contact materials, our semi-finished contact products are used worldwide in a wide range of applications.

Fields of application

- Lighting systems

- Information and data systems

- Automotive electrics

- Automation engineering

- Automatic control science and technology

- Low-voltage power engineering

- Installation technology

- All types of household appliances

Wires

Our wires are made from silver and silver alloys (e.g., AgNi0.15, AgCu3, AgPd30) and powder-metallurgical silver-based materials (e.g., Ag/Ni, Ag/SnO2, Ag/ZnO). They are a high-quality starting product for the manufacture of various contacts and contact parts. This is achieved through a series of carefully controlled processes, including extrusion, drawing, and annealing. All the technologies featured are provided in varying degrees of vertical integration. The typical wire diameters and tolerances range from 0.5 ± 0.01 mm to 4.5 ± 0.04 mm, and sometimes larger.

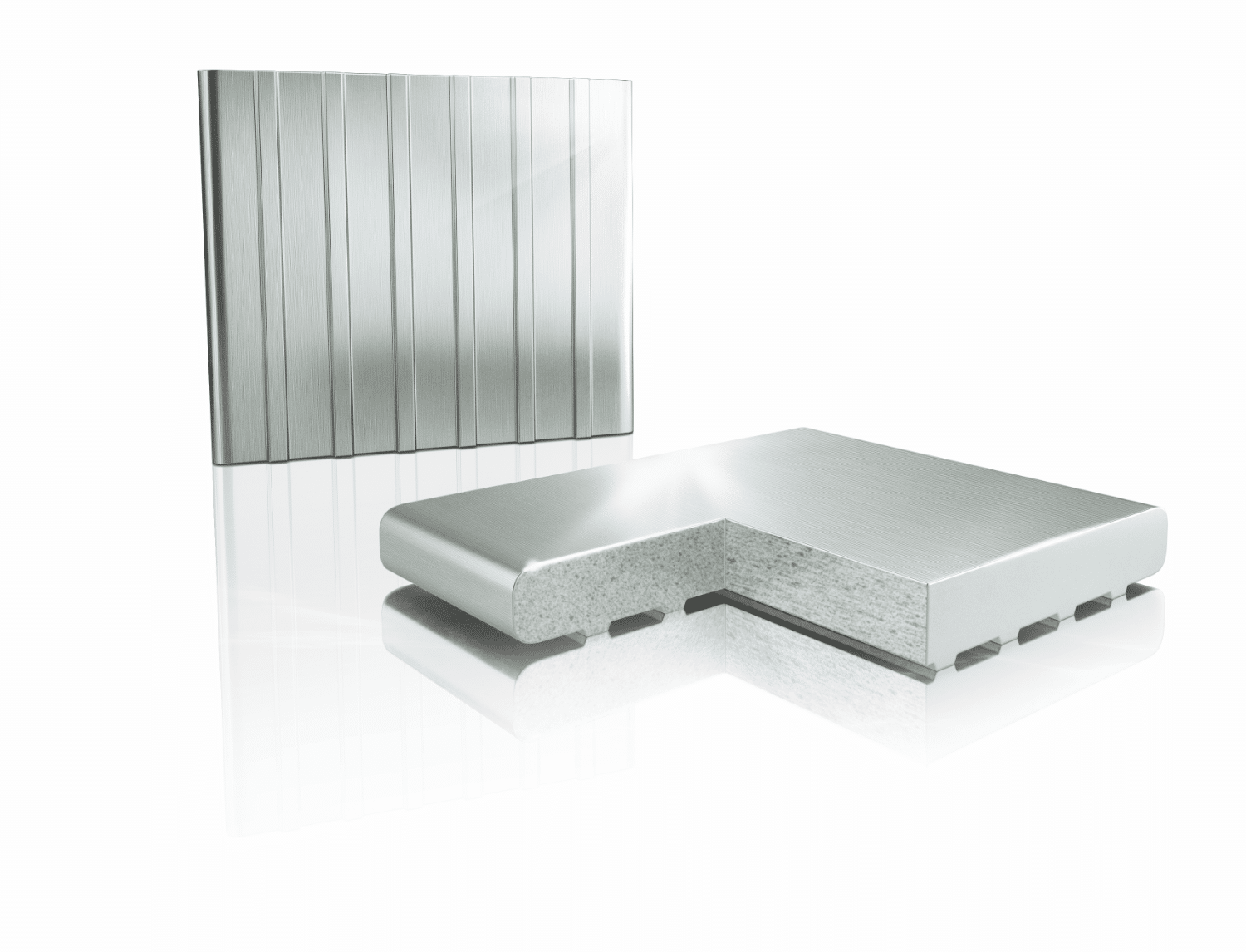

Profiles

Profiles are used as reliable contact elements and are therefore used in relays, switches, push buttons, miniature motors, and actuators. Profiles are manufactured using a solid contact material or a combination of precious and base metals in various layers.

ADVANTAGES OF THE APPLICATION

- Savings on precious metals: There is an opportunity to save on precious metals. It is possible to optimize costs by adjusting the contact size and layer thickness of the precious metal contact material within narrow dimensional tolerances.

- Design options: Depending on the desired application, profiles can be customized in terms of shape and material combination.

- ECost-effectiveness: Profiles have a wide range of applications in the welding industry. They can be used for seam welding in the rolling direction of carrier strip material or for horizontal welding of profile and strip segments.

Contact tips

Contact tips and moulded contact parts are frequently used in power engineering switchgears, often by welding or soldering them to the respective contact carrier. The manufacturing process varies depending on the contact material used.

THE MOST COMMON MANUFACTURING PROCESSES ARE:

- Cutting from extruded bars

- Punching from tapes, strips and clad profiles

- Pressing, sintering and infiltration

- Pressing, sintering and optional repressing